Table of Contents

How to Design a Laboratory Exhaust System: A Comprehensive Guide

Designing a Laboratory Exhaust System is one of the most crucial elements of laboratory planning. An effective Laboratory Exhaust System design ensures a safe environment, protects lab personnel from exposure to harmful chemicals, and maintains air quality control throughout the lab. Whether you are a lab owner or designer, it is essential to create a system that balances safety, efficiency, and regulatory compliance.

This guide outlines how to design an efficient Laboratory Exhaust System, providing helpful tips to make your laboratory safe and operational.

Why a Proper Laboratory Exhaust System Is Essential

Laboratories handle a wide variety of chemicals, some of which may be toxic, flammable, or otherwise hazardous. An inadequately designed Laboratory Exhaust System can lead to the buildup of dangerous fumes and airborne contaminants, putting lab personnel and the surrounding environment at risk.

A well-thought-out Laboratory Exhaust System design will:

a. Control the spread of harmful pollutants.

b. Maintain a safe working atmosphere by keeping air free from contaminants.

c. Ensure compliance with local and international safety standards.

d. Optimize energy efficiency while maintaining proper airflow.

Key Factors to Consider in Laboratory Exhaust System Design

Types of Exhaust Systems

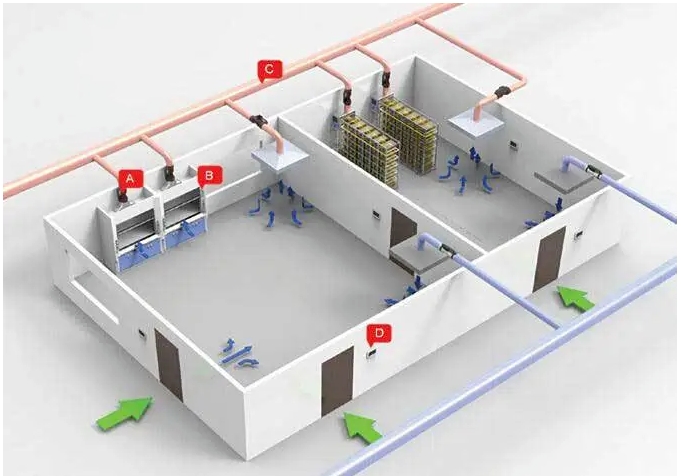

Laboratories generally use two primary types of exhaust systems: local exhaust systems and comprehensive exhaust systems.

- Local Exhaust Systems: These are used to capture and remove hazardous substances directly at the source. Examples include fume hoods and extraction arms. Local exhaust systems are efficient, reduce energy consumption, and ensure that harmful substances are eliminated before they disperse into the lab.

- Comprehensive Exhaust Systems: When local exhaust systems are insufficient, comprehensive systems provide broader air circulation, removing contaminants from larger areas. This is necessary in labs with higher pollutant volumes or where hazardous substances may spread beyond localized areas.

Ventilation Requirements

The airflow in a lab must meet specific requirements to ensure that contaminants are safely removed. The general rule for Laboratory Exhaust System design is to achieve air changes at a rate of 12-15 times per hour. However, this can vary depending on the type of lab and the nature of the experiments being conducted.

For specialized laboratories, such as cleanrooms or biosafety labs, specific technical ventilation standards must be adhered to, making it crucial to assess the lab’s needs early in the design phase.

Energy Efficiency

Energy consumption is a significant factor in lab design, particularly for Laboratory Exhaust Systems. Systems that continuously exhaust air from the lab require substantial energy, especially if they use untreated fresh air from outside.

One way to optimize energy usage is by implementing Variable Air Volume (VAV) systems. These systems adjust the airflow based on real-time requirements, reducing the energy load during off-peak times while ensuring safety when the lab is fully operational.

Choosing the Right Fume Hood

The fume hood is a critical component of a Laboratory Exhaust System. Modern fume hoods, especially those using VAV technology, are designed to provide adjustable airflow depending on the sash position, maintaining a steady face velocity of approximately 0.5 m/s for safety.

When choosing a fume hood, consider:

- The type of experiments conducted.

- The volume of hazardous materials used.

- Energy efficiency features, such as automatic airflow adjustment.

- Compliance with safety standards, including alarms for face velocity fluctuations.

Designing an Effective Laboratory Exhaust System

Site Evaluation and Lab Layout

Before beginning the design, evaluate the lab’s layout and usage. Identify the areas where hazardous substances will be handled and plan for appropriate local exhaust points. Additionally, map out the air circulation pathways to avoid short-circuiting, where exhaust air re-enters the lab space.

In labs with specialized needs, such as biosafety or animal labs, the exhaust system should be tailored to the specific safety requirements of each area. For example, biosafety labs require negative pressure environments to prevent cross-contamination between rooms.

Proper Ventilation Ductwork Design

The ductwork is an essential part of any Laboratory Exhaust System. Improperly designed duct systems can lead to pressure drops, airflow inefficiencies, and increased energy costs. When planning your ductwork:

- Use appropriate materials, such as stainless steel or polypropylene, depending on the chemicals used in the lab.

- Ensure the ducts are properly sized to handle the airflow rates required for the lab’s safety.

- Include dampers or control valves to regulate airflow to different areas of the lab.

Implementing Variable Air Volume (VAV) Systems

VAV systems allow labs to adjust the amount of air being exhausted based on real-time demand, saving energy when airflow needs are lower. This feature is particularly useful in labs with multiple fume hoods or other exhaust equipment, allowing for flexibility in ventilation without compromising safety.

Comprehensive Exhaust and Air Supply Balance

A well-designed Laboratory Exhaust System needs to be balanced with an appropriate air supply system. The air being exhausted must be replaced with fresh air to maintain safe working conditions. This can be done through mechanical air supply systems or, in smaller labs, through natural air infiltration via windows and doors.

To ensure proper balance:

- Use pressure sensors to monitor the airflow and adjust the supply and exhaust volumes accordingly.

- Design the lab with slight negative pressure to prevent the escape of hazardous substances into adjacent areas.

- Set minimum ventilation rates to ensure consistent air changes throughout the day and night.

Conclusion

An effective Laboratory Exhaust System design is essential for maintaining a safe, efficient, and compliant lab environment. By understanding the specific needs of the lab, selecting appropriate exhaust systems, optimizing energy efficiency with VAV systems, and ensuring a balance between exhaust and air supply, lab designers and owners can create a system that meets safety standards while reducing operational costs.

If you are planning a new lab or upgrading an existing one, taking the time to properly design your Laboratory Exhaust System will result in a safer and more energy-efficient workspace for years to come.