In today’s advanced industries, controlling the environment is crucial for maintaining high-quality standards. Cleanrooms, with their controlled environments, are essential for various industries, from pharmaceuticals to electronics. If you’re considering building a cleanroom or want to learn more about cleanroom projects, this guide will walk you through everything you need to know—from defining cleanroom projects to choosing the right contractor and ensuring compliance with industry standards.

Table of Contents

Definition

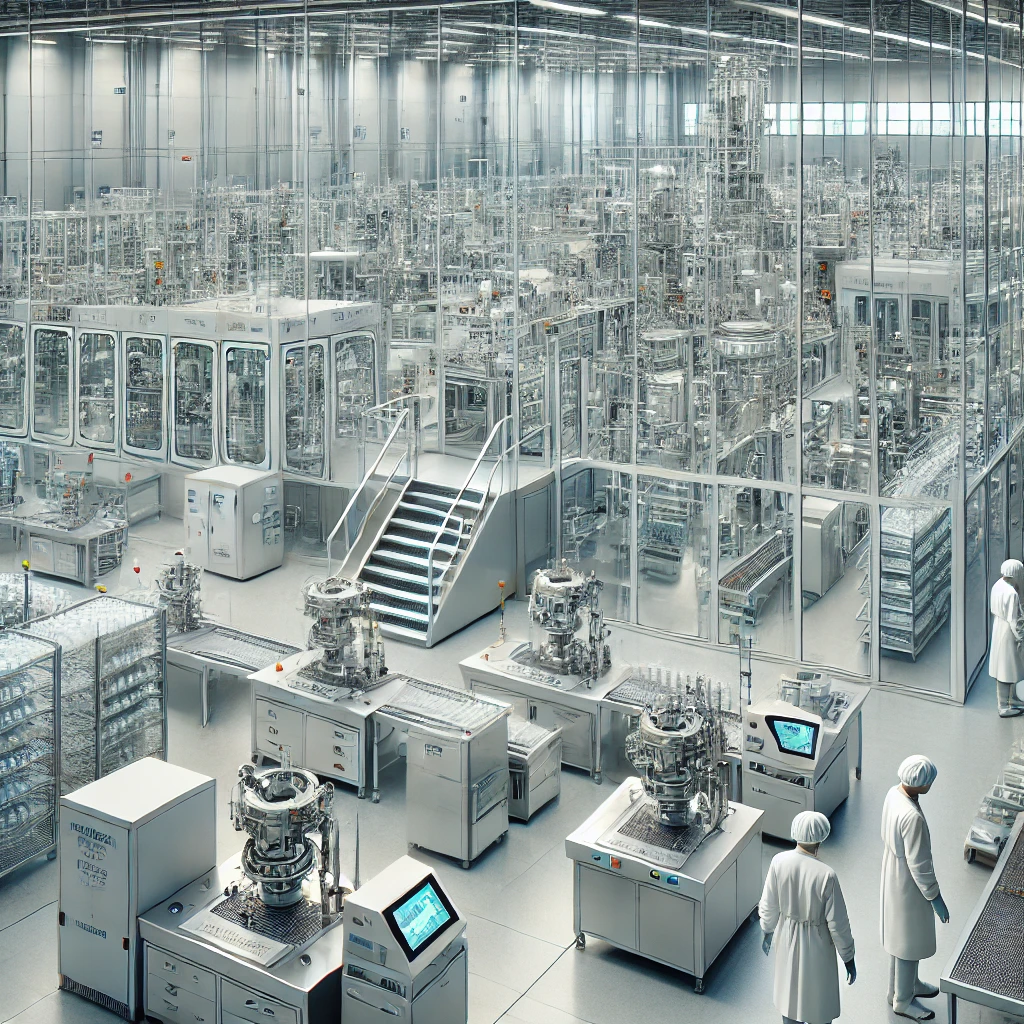

A cleanroom project involves the design, construction, and commissioning of an environment where airborne particles, contaminants, and pollutants are strictly controlled. These spaces are designed to maintain the cleanliness level needed for critical manufacturing processes. A cleanroom can range from a small, enclosed room to large spaces, depending on the project’s scope.

Cleanrooms are essential for industries where even the smallest particle of dust or bacteria can compromise the product or process, including semiconductors, pharmaceuticals, biotechnology, and aerospace industries. Cleanroom projects require specialized expertise, including HVAC systems, HEPA filters, and positive or negative air pressure management to ensure that airborne particles remain within acceptable limits.

Types of Cleanroom Projects

Cleanroom projects can be categorized based on their design, complexity, and industry needs. Below are the most common types of cleanroom projects:

Modular Cleanroom Projects

Modular cleanrooms are pre-engineered, and their components are constructed off-site, which allows for faster installation. These cleanrooms are ideal for businesses that need flexibility and scalability, as they can easily expand or modify the space as needed.

Stick-Built Cleanroom Projects

Stick-built cleanrooms are custom-designed and built on-site. These cleanrooms are perfect for industries with very specific requirements, such as pharmaceutical or semiconductor manufacturing. Stick-built projects allow for more flexibility in design, but they require more time and coordination between contractors and engineers.

Softwall Cleanroom Projects

Softwall cleanrooms use flexible curtains as their walls and are ideal for applications that require portability or temporary clean environments. They are often used for isolating equipment or smaller workstations within a larger cleanroom area.

Hardwall Cleanroom Projects

Hardwall cleanrooms provide a permanent, sturdy, and more controlled environment. They use rigid, solid materials such as steel or glass, making them ideal for long-term installations that require higher cleanliness standards.

Classification of Cleanrooms

Cleanrooms are classified according to the number of particles per cubic meter (or cubic foot) allowed in the air. The most commonly used classification standards include the ISO standards and Federal Standard 209E. Below are the key classifications:

ISO Classification

ISO Class 1: The cleanest level of a cleanroom, allowing only 10 particles per cubic meter.

ISO Class 5: Commonly used in pharmaceuticals and semiconductor industries, allowing up to 3,520 particles per cubic meter.

ISO Class 8: This class allows up to 3,520,000 particles per cubic meter and is often used in less critical environments such as medical device assembly.

Federal Standard 209E

Class 1: The highest level of cleanliness (similar to ISO Class 1).

Class 100: Equivalent to ISO Class 5.

Class 100,000: Equivalent to ISO Class 8.

Choosing the correct classification depends on the industry, regulatory requirements, and the types of processes or products being handled in the cleanroom.

What Industry Will Need a Cleanroom?

A variety of industries require cleanrooms to ensure product quality, safety, and compliance with regulations. Below are the primary sectors that rely on cleanroom projects:

Pharmaceutical Industry

Pharmaceutical companies need cleanrooms for drug manufacturing, formulation, and packaging. The cleanroom environment helps eliminate contaminants that could degrade drug quality or pose health risks to patients.

Semiconductor and Electronics Industry

Microchip manufacturing requires ultra-clean environments to ensure that dust particles do not interfere with the sensitive components. Cleanrooms are vital for fabricating and assembling semiconductors, printed circuit boards, and other electronic components.

Biotechnology and Life Sciences

Cleanrooms in biotechnology are used for tissue culture, genetic research, and the production of vaccines and medical devices. These facilities need high-level contamination control to maintain the integrity of their processes.

Aerospace Industry

In aerospace, cleanrooms are used to assemble and test sensitive components like satellite instruments, which can be compromised by even the smallest particles.

Food and Beverage Industry

Food production companies utilize cleanrooms to reduce contamination risks during packaging and processing, ensuring that their products meet food safety standards.

What Equipment Is Used in a Cleanroom?

The equipment used in a cleanroom plays a critical role in maintaining the clean, controlled environment. Here are some key pieces of equipment that are typically included in a cleanroom project:

HEPA and ULPA Filters

These filters are critical in capturing airborne particles. HEPA (High-Efficiency Particulate Air) filters can remove 99.97% of particles as small as 0.3 microns, while ULPA (Ultra-Low Penetration Air) filters capture even smaller particles.

Laminar Flow Workbenches

Laminar flow hoods provide a clean, particle-free work area by using HEPA filters to direct a constant flow of clean air over the workspace.

Cleanroom Pass Boxes

Pass boxes are used to transfer materials between clean and non-clean areas without compromising the cleanliness of the environment.

Cleanroom Garments

Personnel working in cleanrooms wear special garments, including gloves, gowns, face masks, and hoods, to minimize contamination risks.

Air Showers

Before entering a cleanroom, workers and materials may pass through air showers that blow off particles from their clothing and surfaces.

How to Choose a Cleanroom Project Contractor

Choosing the right contractor for your cleanroom project is essential for ensuring quality, cost-effectiveness, and compliance. Here are key factors to consider when selecting a cleanroom contractor:

Experience and Expertise

Look for contractors who specialize in cleanroom design and construction with proven experience in your industry. Check their past projects and ask for references from clients with similar needs.

Industry Knowledge

Ensure that the contractor has a deep understanding of industry regulations and standards (e.g., ISO classifications, FDA guidelines). They should be able to design a cleanroom that meets all necessary compliance standards.

Customization and Flexibility

Every cleanroom project is unique. Choose a contractor who can offer customized solutions tailored to your specific requirements, including modular or stick-built designs.

Communication and Project Management

A cleanroom project requires close coordination between the contractor, engineers, and other stakeholders. Make sure the contractor has strong project management skills and communicates effectively throughout the project lifecycle.

Budget and Timelines

Get multiple quotes and compare them not only on price but also on quality and timeline. A contractor who can stay within budget and meet deadlines is crucial for a successful cleanroom project.

How to Test If the Cleanroom Meets Industry Requirements

After the construction of a cleanroom, it is essential to test whether it meets the required standards for cleanliness and performance. Below are common methods used to evaluate a cleanroom’s performance:

Particle Counting

A particle counter is used to measure the number and size of airborne particles in the cleanroom. This test ensures that the cleanroom complies with its ISO classification.

Airflow and Ventilation Testing

Tests such as airflow velocity and pressure differential measurements are conducted to ensure the cleanroom’s HVAC system is maintaining proper airflow patterns and pressure gradients.

HEPA/ULPA Filter Integrity Testing

Leak tests are performed on HEPA and ULPA filters to ensure they are functioning properly and capturing airborne particles as required.

Surface Cleanliness Testing

Swab testing or contact plates can be used to test the cleanliness of surfaces in the cleanroom, ensuring there is no contamination that could compromise operations.

Certification

Once all tests are completed, the cleanroom must be certified by a third-party auditor to verify that it meets the necessary industry standards and specifications.

Conclusion

A cleanroom project is a significant investment that requires careful planning, expert execution, and rigorous testing. Whether you’re in the pharmaceutical, semiconductor, or food industry, the right cleanroom design can make all the difference in ensuring product quality and regulatory compliance. By understanding the types of cleanroom projects, selecting the right contractor, and thoroughly testing your cleanroom, you can ensure your project’s success and maintain a contamination-free environment.