Table of Contents

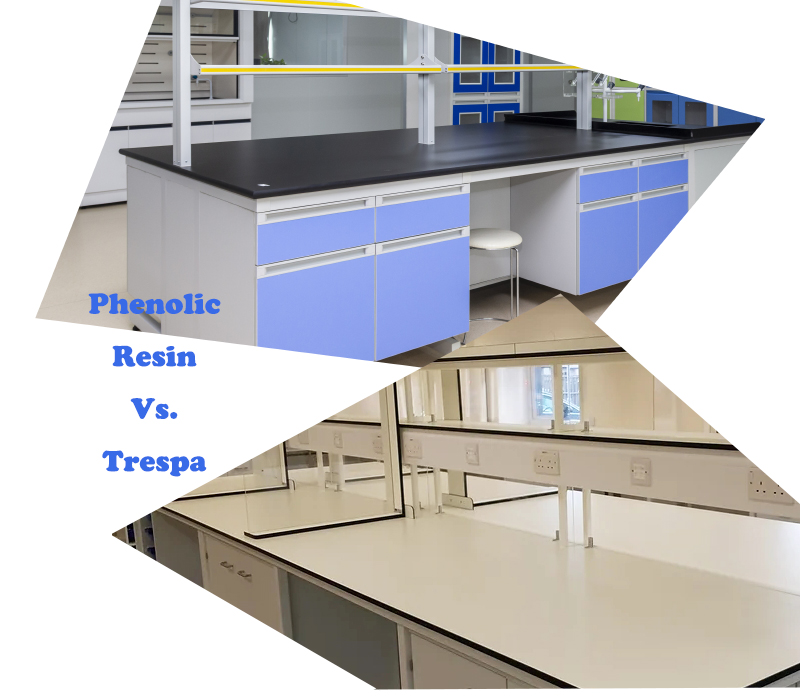

Trespa worktop and phenolic resin worktop are both popular materials used for laboratory, but they have some key differences. Here’s a comparison:

Material Composition

- Trespa: Made from a high-pressure laminate (HPL) material, Trespa is a composite consisting of thermosetting resins, reinforced with wood fibers and cured at high pressure and temperature. It has a decorative surface, often used for both lab worktops and cladding.

- Phenolic Resin: Phenolic resin worktops are made from layers of kraft paper impregnated with phenolic resin, then pressed under high heat and pressure to form a solid, non-porous material. It doesn’t contain wood fibers and is completely synthetic.

Durability

- Trespa: Highly resistant to scratches, wear, and impact. It also has good resistance to most chemicals but can degrade when exposed to harsh chemicals over time.

- Phenolic Resin: Superior chemical resistance compared to Trespa, especially in environments where heavy chemical use occurs. It’s highly durable and suitable for more intense laboratory settings, including chemical labs and wet environments.

Chemical Resistance

- Trespa: Offers moderate chemical resistance, enough for general laboratory use. However, it’s less resistant to aggressive chemicals and acids.

- Phenolic Resin: Highly resistant to a wide range of chemicals, making it ideal for use in labs that handle corrosive substances like acids, solvents, and strong bases.

Moisture Resistance

- Trespa: Resistant to moisture, but may not be as ideal as phenolic resin in consistently wet environments.

- Phenolic Resin: Exceptionally water-resistant, making it ideal for labs that involve water or humidity.

Appearance

- Trespa: Known for its aesthetic appeal, Trespa surfaces can be designed with a wide range of colors and finishes, providing more decorative options for lab environments.

- Phenolic Resin: Usually comes in solid, dark colors (like black or gray), and its design options are more limited compared to Trespa.

Cost

- Trespa: Generally more expensive than phenolic resin due to its high-pressure laminate process and versatile applications.

- Phenolic Resin: More affordable and widely used for its durability and functionality, particularly in industrial or chemical-heavy labs.

Applications

- Trespa: Common in general labs, educational settings, and areas where aesthetics and moderate chemical resistance are important.

- Phenolic Resin: Preferred in high-demand chemical labs, wet labs, and environments that require strong chemical and moisture resistance.

In summary, Trespa worktop is ideal for general laboratory use and offers more design flexibility, while phenolic resin worktop is better suited for labs that require high chemical and moisture resistance.